Part of what makes the job of an architect or designer so gratifying is the opportunity to make the experience of the built environment better for people in both big and small ways.

At OZ Architecture, we’re always looking for ways to advance the art and science of design – to push ourselves to find the very best solutions within the context of a project. Our work on The Loading Dock, Colorado’s first cross-laminated timber (CLT) office building is a great example of our constant pursuit of the extraordinary.

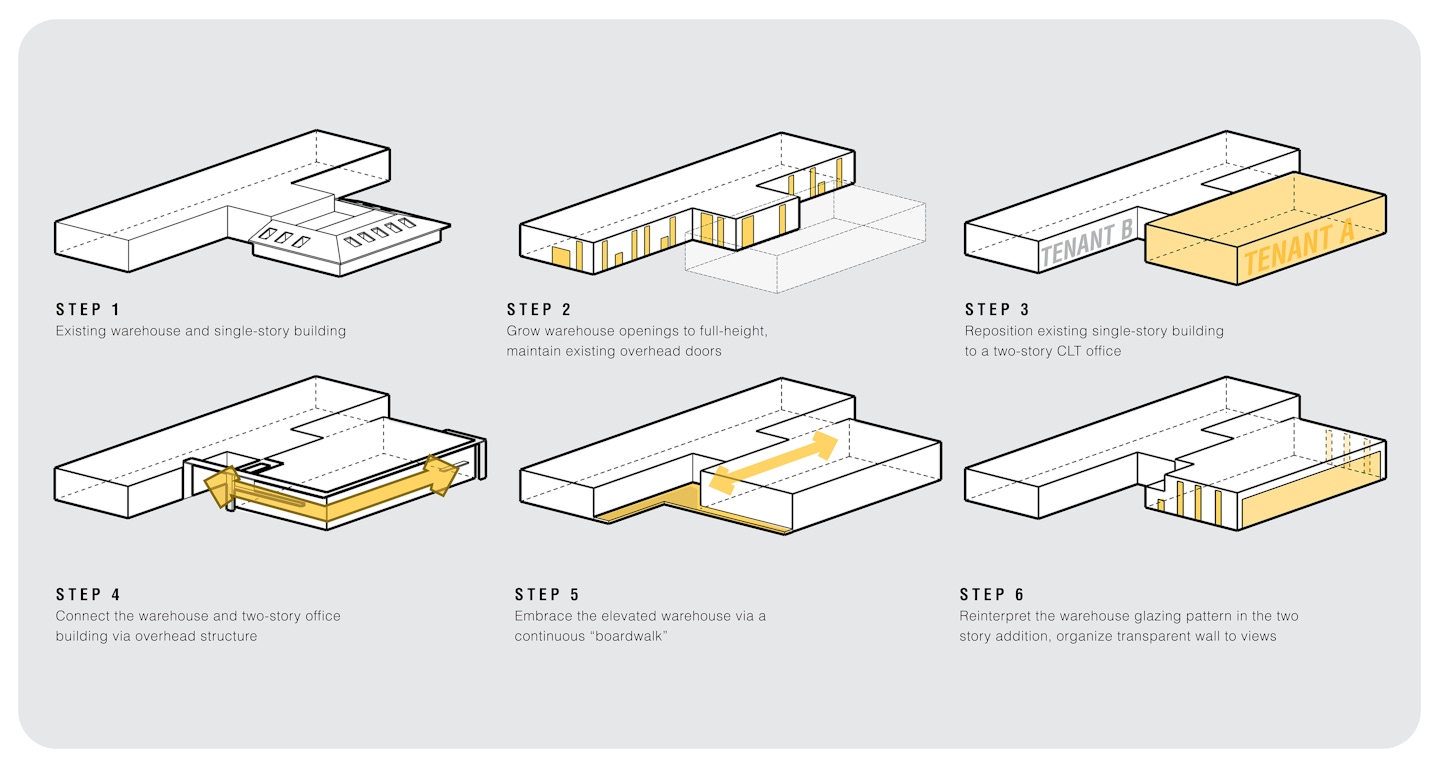

This transformative project consisted of the renovation of a 32,000-square-foot warehouse and the construction of a connected 32,000-square-foot, two-story mass timber office building in Boulder, Colorado. The potential for future development in this office park and community required a distinctive solution that highlighted an honest use of materials – one that exposed the beautiful structure, and unique connections and details.

To this end, we took a holistic approach, from materiality to design elements, with innovating solutions that hadn’t been introduced into this community before. In fact, this project is one of the first in the nation to fully integrate top-to-bottom exposed wood, with glue-laminated beams and columns, CLT interior walls, exposed CLT ceilings, and structural wood storefront. The exposed wood structure is visible from both outside and inside, providing tenants with a contemporary, yet authentic, workplace.

The project was deemed “The Loading Dock” because the existing warehouse consisted of loading areas along the exterior facade. The design team embraced this idea by proposing an elevated boardwalk to seamlessly connect the renovated warehouse to the mass timber office. This also provided much needed indoor-outdoor amenity space and landscaping that surrounds the entire project. This boardwalk is highlighted by floor-to-roof glazed openings to connect and provide daylight to the interior. This area also features a cantilevered mass timber canopy and lighting for various events.

Innovation in Materiality

Given the level of innovation on this project, material selection was a major design driver. The CLT used in the project was prefabricated, which allowed the team to design unique details to showcase the wood’s inherent beauty. Columns are lifted from the ground with steel bases to emphasize their form as well as support long-term maintenance. The pine/spruce mix is exposed throughout with a light transparent sealer to both protect and expose the beautiful warmth of the natural wood.

Exposed spiral ducts and lowered interior walls help ensure the natural wood ceilings remain unmarred. Glue-laminated beams were pre-cut for lighting conduit to run continuously, and power/data cables were concealed in the floor to keep the wood ceiling clean and exposed. The column head steel is minimized and hidden within the columns to showcase the beautiful simplicity of the connection detail. Exposed CLT soffit wood on the exterior provides a wonderful foreshadowing of the internal beauty.

Why CLT?

In a technology-centered world, we are also seeing a strong desire to reconnect people to a tactile environment through spaces that utilize natural materials, authentic character, and modern amenities. For The Loading Dock, we created an open, inclusive interior environment that actively encourages collaboration and connectivity, with the wood lending the benefits of biophilia, which promotes employee well-being and happiness. The material selection has the added benefit of supporting improved thermal performance, energy efficiency, and improving air quality as well as performing well acoustically. The result is the ideal environment for employee productivity.

CLT has been gaining in popularity, particularly in office applications, for all of the reasons above, but also because it can function as a more sustainable building material than steel or concrete, by virtue of the fact that it requires fewer emissions to produce and serves to trap C02. In this case, the use of mass timber allowed us to reduce waste on the project as the structural material is also the finish material which reduces the need for other carbon emissive material needs.

The team is proud and fortunate to have worked with mass timber in this way and demonstrated the possibilities for the future. The OZ team is currently working on several other projects which similarly seek to deliver innovative design using mass timber and we look forward to sharing more as those projects progress!